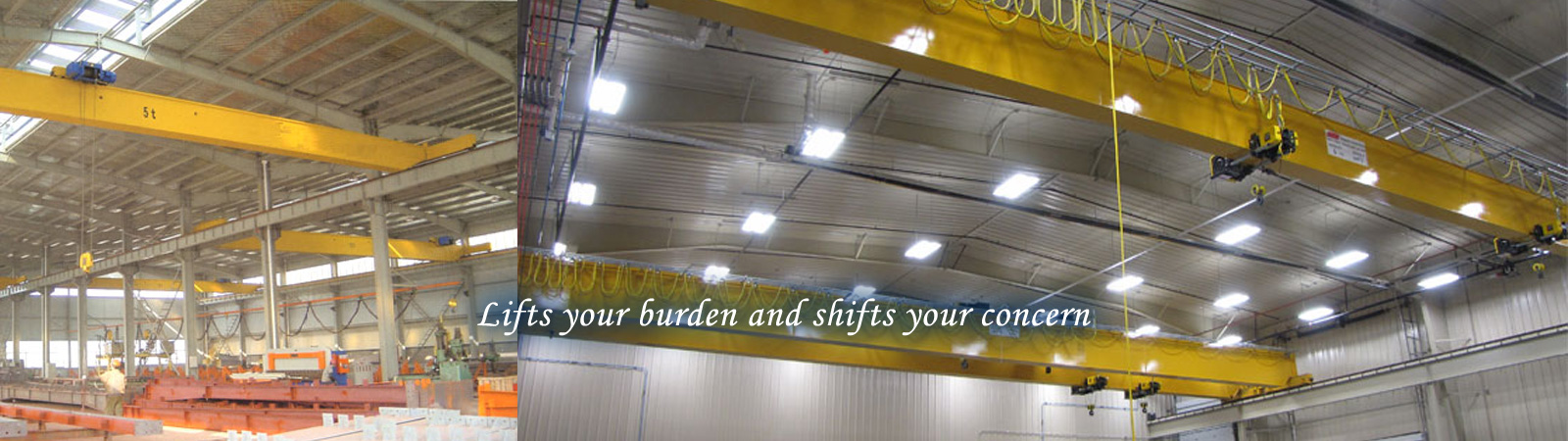

Double Girder E.O.T Crane

Customers can avail from us a remarkable range of Double Girder EOT Crane. All our products are manufactured using excellent quality raw material by employing latest machines and tools. Owing to reliability and minimal maintenance, these cranes find their application in various industrial sectors.

We are among the prominent organizations engaged in manufacturing and supplying superior quality Double Girder EOT Crane. These Double Girder EOT Crane are used for material handling and are best suited for both medium and heavy duty operations. These kind of Cranes are generally used when heavy loads and wide spans are needed. These double girder EOT cranes are widely used in lifts, hoisting, cross & long travel speeds to suit the client's requirement.

Lifton manufactures Double Girder Bridge Crane (Double Girder EOT Crane) in different configurations. It is manufactured with rigid and compact steel structures, less consumption of electricity, low noise levels make our rail mounted cranes more user friendly. Double Girder Cranes can be offered for a very large range of spans, large range of heights of lift as well as a large number of speeds. They can also be provided with multiple hoisting trolleys running on the same bridge.

Double-girder suspension cranes enable goods of all kinds to be transported with ease. They provide area-serving, overhead handling and guarantee fast, reliable and precise positioning even for heavy loads and large span dimensions.

- Cost-effective implementation

- Modular system design

- Smooth and reliable handling

- Favourable installation dimensions

Optimum Space Utilisation

- Overhead, area-serving load transport

- Optimum utilisation of space thanks to minimum approach dimensions

- Suspension from existing workshop ceilings or roof structures

- Require no additional supports for the crane runway

Convenient Handling

- Simple, safe and reliable handling

- Favourable installation dimensions

- Customer-specific and cost-effective solutions for workshops – also in limited sections

Strong performance

- Maximum possible hook paths by arranging the hoist between the crane girders

- Maximum span dimensions by means of multiple suspensions (cranes operating on more than two runways) - to cover extensive storage and production areas

- Modular system design